Online inspection system improves the quality of spunlace non-woven fabric manufacturers

Online inspection system improves the quality of spunlace non-woven fabric manufacturers

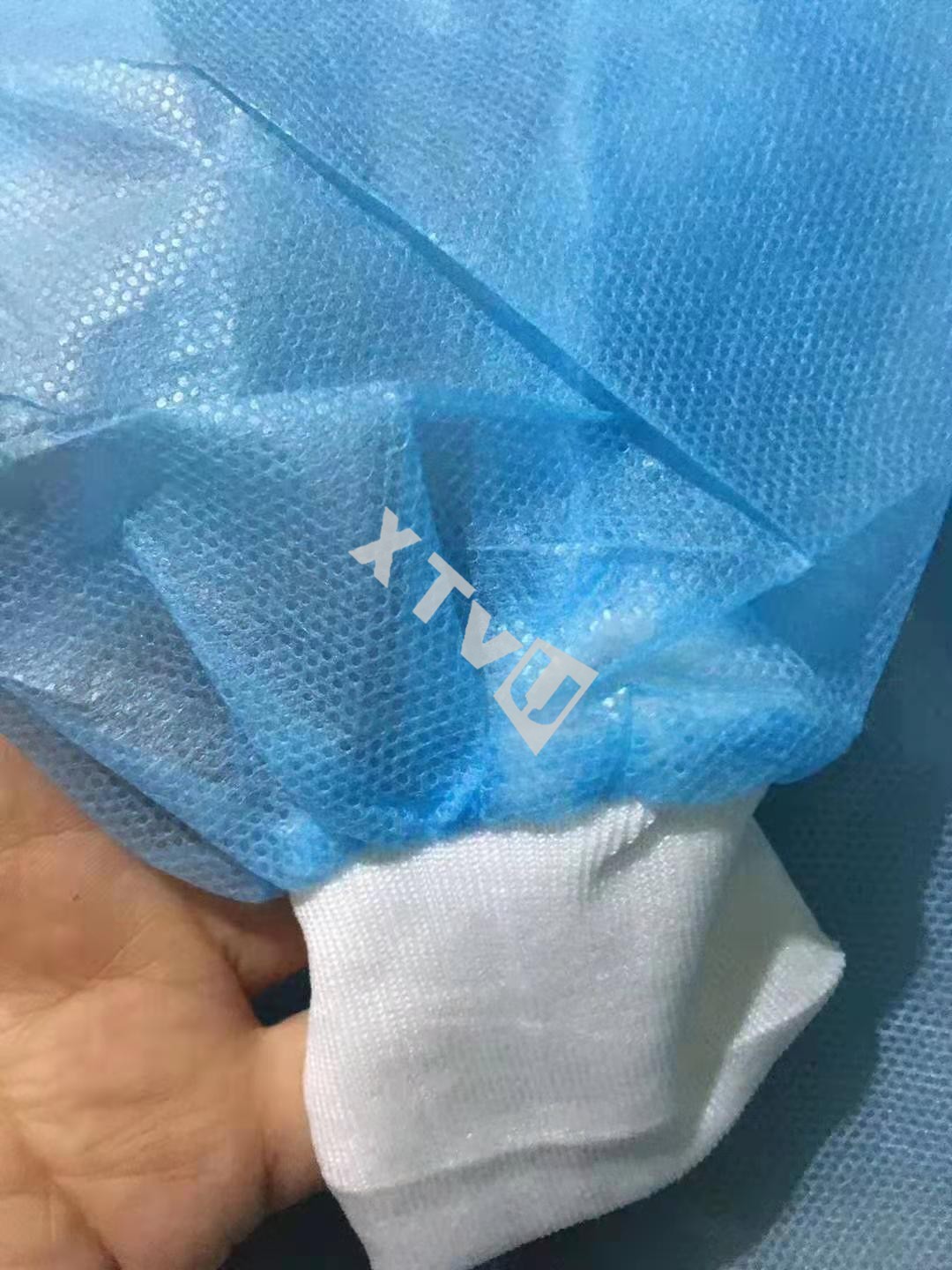

For products with important end-uses, their raw materials cannot be compromised in quality. For example, non-woven fabric manufacturers must ensure the highest level of quality when providing raw materials for medical, personal care and hygiene products. These products must have an almost perfect appearance and feel to meet the desired standards of cleanliness and comfort, especially for products that require contact with human skin during use.

Online inspection system improves the quality of spunlace non-woven fabric manufacturers

Therefore, any contamination in the fabric creates a potentially

catastrophic quality risk, leading to customer claims and reject

rejections. It is absolutely zero tolerance for defects greater than 1

mm. However, tiny foreign matter in the fiber can still form unsightly

flaws, and it may also cause the user's skin to scratch or scratch.

In general, fabrics used for sensitive applications are made using

spunlace technology. The starting material is loose fiber morphology.

The key stage for removing any impurities is before starting the weaving

process. At the same time, nonwovens manufacturers must retain as much

valuable "quality" fiber as possible to reduce losses in order to

maintain plant efficiency and profitability.

Online inspection system improves the quality of spunlace non-woven fabric manufacturers

The USTER® JOSSI VISION SHIELD fiber cleaning system is the ideal solution. It can detect and remove contamination to the maximum extent, reducing raw material loss. The system works in an ideal position. After the fine opening process in the clearing plant, the latest spectrometer technology is used to accurately position the tiny foreign particles in the raw materials of cotton or man-made fibers.

Online inspection system improves the quality of spunlace non-woven fabric manufacturers

The USTER® JOSSI VISION SHIELD has a wider wavelength range than conventional camera systems and can recognize and remove impurities as fine as human hair. In the fiber preparation process, sufficient opening of the fiber bundle can be achieved, so that the detection effect is enhanced to prevent any fine impurities from hiding during the process.

Online inspection system improves the quality of spunlace non-woven fabric manufacturers

Once identified, foreign fiber impurities will be automatically

discharged by the system to prevent contamination of the spunlace

nonwoven. Although the loss cannot be completely avoided, the USTER®

JOSSI VISION SHIELD can continuously measure the speed of fiber bundle

passing. Then, the system uses precise valves to precisely control the

time of each injection, so that only harmful impurities are removed and

the fiber can be spun. The loss is controlled at a very low level, which

significantly saves the manufacturer's production costs.

Online inspection system improves the quality of spunlace non-woven fabric manufacturers

-

2023-04-21

What is the main adv…

What is the main advantage of …

-

2023-04-21

Are nonwovens washab…

Are nonwovens washable and bre…

-

2023-04-21

Where are nonwoven f…

Where are nonwoven fabrics use…

-

2023-04-21

Are nonwoven fabrics…

Are nonwoven fabrics environme…

-

2023-04-21

What are the raw mat…

What are the raw materials for…