needle punch nonwoven fabric manufacturers

needle punch nonwoven fabric manufacturers

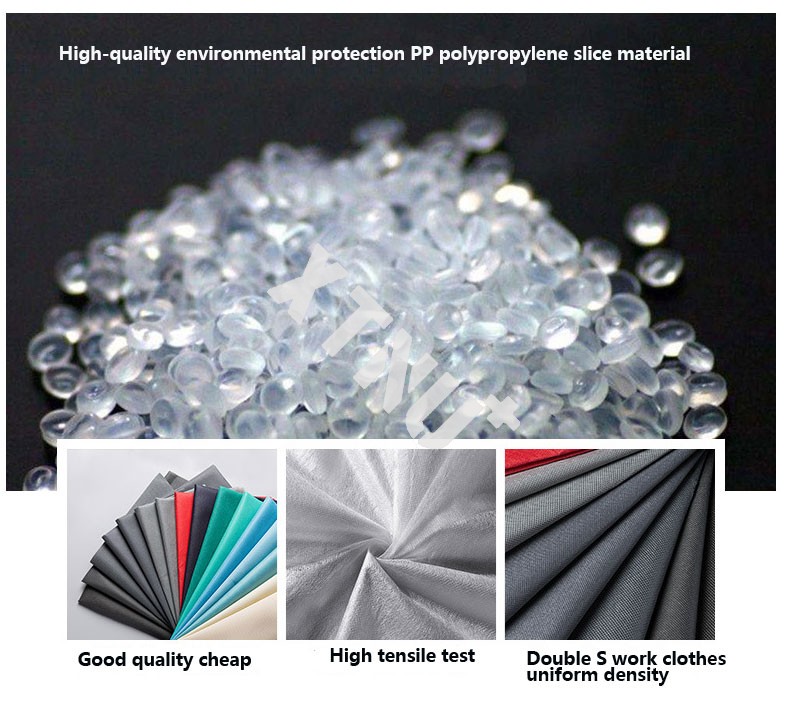

If the methyl is disorderly arranged on both sides of the molecular backbone, it is called atactic polypropylene. Due to crystallization, the PP shrinkage is quite high, typically 1. PP has no problem of environmental stress cracking. When the methyl groups are alternately arranged on both sides of the molecular chain, they are called syndiotactic polypropylene, low gloss and low rigidity, but they have stronger impact strength.

needle punch nonwoven fabric manufacturers

The impact strength of PP is

related to ethylene content. The increase increases. PP has a Vicat

softening temperature of 150°C and is the lightest universal plastic.

The disadvantage is poor low temperature impact resistance. Due to the

highly structured structure, the melting point can be as high as 167°C.

The melt flow rate (MFR) of PP is usually from 1 to 100. PP materials

with low MFR have better impact resistance but lower strength. For the

same MFR material.

-

2023-05-13

Disposable Protectiv…

Disposable Protective Nylon Be…

-

2023-05-13

Wholesale Nonwoven B…

Wholesale Nonwoven Beard Cover…

-

2023-05-13

Disposable PE pedicu…

Disposable PE pedicure liner/s…

-

2023-05-13

Disposable Blue PE p…

Disposable Blue PE pedicure li…

-

2023-05-13

XTNU Non-skid blue s…

XTNU Non-skid blue shoe cover …