Manufacturers teach you how to detect non-woven bags

Manufacturers teach you how to detect non-woven bags

The quality inspection of the first batch should clearly understand the contract or relevant production requirements of the batch of bags. Understand the quality standards of the batch of products. If the contract requires the use of 90 grams of non-woven fabrics, but the manufacturers use 70 grams of non-woven fabric, it does not meet the requirements. of. How to check the quality of non-woven bags, many manufacturers will be based on their own experience in this line to determine the quality of non-woven bags, the following non-woven bags manufacturers to introduce how to detect non-woven bags.

Manufacturers teach you how to detect non-woven bags

The inspection bag must first check the appearance, the appearance of

the standard is relatively easy to judge no broken line, no error is

generally no problem; then the test is environmental protection:

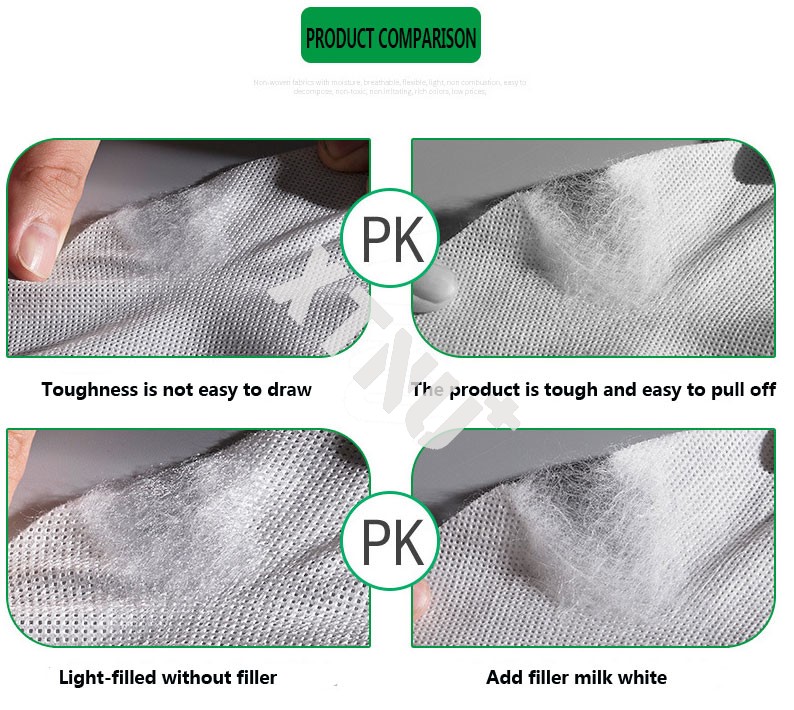

qualified non-woven can moisture, toughness, sterilization and other

characteristics under the sniffing No odor proves that the product is

qualified.

Manufacturers teach you how to detect non-woven bags

Summarized as follows:

1. Inspect the non-woven bag material: check the inspection certificate of the raw material of the non-woven bag.

2. Sensory inspection of non-woven bag quality

(1) Observe the color: In the natural light, visually measure whether the color of the non-woven bag is the same as that of the sample bag.

(2) Odor-smelling: Using olfactory to identify whether the non-woven bag has a pungent odor (for fabrics and printed patterns).

(3) Inspection of appearance quality of non-woven bags: visual observation under natural light, to see if the appearance of the bag is square, and to check the thickness of the raw material non-woven fabric by the hand-feeling method.

(4) Inspection of dimensional deviations: Non-woven bags were measured using a ruler with a minimum scale of 1 mm.

(5) Non-woven bag sewing requirements inspection: sewing appearance, the non-woven bag is flatly spread on the inspection table and measured with a ruler and visual inspection.

(6) Stitch Density: Count the number of stitches after measuring the length of each 3cm section with a ruler.

(7) Non-woven bag suture strength: According to the provisions of GB/T 3923.1-1997. Samples were taken on a non-woven bag. The sample was 300 mm long and 50 mm wide. Suture the specimen at both ends of the suture, should retain the length of the four-needle suture and knot at the end to prevent the suture from escaping.

3. Finally, the quality of the test can also be verified using physical machinery for physical and mechanical properties.

Manufacturers teach you how to detect non-woven bags

-

2023-05-13

Disposable Protectiv…

Disposable Protective Nylon Be…

-

2023-05-13

Wholesale Nonwoven B…

Wholesale Nonwoven Beard Cover…

-

2023-05-13

Disposable PE pedicu…

Disposable PE pedicure liner/s…

-

2023-05-13

Disposable Blue PE p…

Disposable Blue PE pedicure li…

-

2023-05-13

XTNU Non-skid blue s…

XTNU Non-skid blue shoe cover …